As electric vehicles (EVs) become more widespread, the importance of the On-Board Charging Unit (OBC) is increasingly apparent. The OBC not only provides power to EVs but also manages the charging state of the battery, ensuring its longevity and performance. Therefore, the OBC's functionality directly impacts the overall experience of using an electric vehicle.

With the rapid growth of the EV industry, trends toward smart, lightweight, and integrated solutions are shaping the future of electric vehicles. The OBC plays a crucial role in this development, as it directly influences the safety, stability, and power density of EVs. The power density of the OBC impacts the vehicle’s overall weight, range, and charging time.

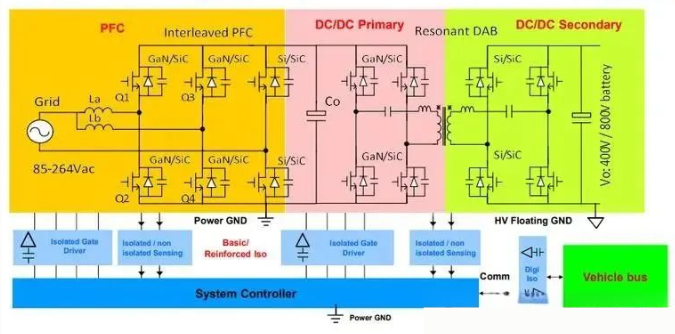

Silicon carbide (SiC), a third-generation semiconductor, offers impressive capabilities such as high-temperature resistance, high voltage tolerance, high frequency, and radiation resistance. Utilizing SiC power devices can reduce power conversion losses in EVs and hybrid vehicles by about 20%. Applying SiC power devices to OBCs is instrumental in enhancing efficiency, power density, and quality density.

The bidirectional on-board charger (OBC) is a charging device installed in electric vehicles that enables two-way energy flow between the EV and the grid. This feature allows the OBC not only to meet the EV’s charging requirements but also to feed energy back to the grid during peak demand or supply power to homes, thus improving energy flexibility and efficiency.

Bidirectional OBCs allow for two-way energy flow, increasing energy efficiency and providing EV users with more flexibility. For example, EV owners can sell electricity back to the grid during peak hours or use the vehicle as a backup power source in emergencies. Additionally, bidirectional OBCs contribute positively to grid stability and the integration of renewable energy sources.

The high voltage tolerance of SiC devices makes them ideal for high-voltage applications in OBCs, as they withstand higher voltages, reduce circuit board size and weight, and increase system efficiency. Due to their fast switching speed and low loss, SiC devices enable rapid charging, reducing charging times and enhancing user experience. The high efficiency of SiC devices means less energy waste during charging, leading to lower charging costs. Moreover, the thermal stability of SiC devices allows them to function in high-temperature environments, which is essential for EVs under varying conditions.

The working principle of bidirectional OBCs encompasses two main functions: charging the EV from the grid (AC to DC conversion) and supplying the EV’s stored energy back to the grid or other systems (DC to AC conversion). When connected to an AC power source, such as a household outlet or public charging station, the OBC first receives AC, then uses an AC-DC converter with a rectifier to convert the AC to DC, which then charges the EV’s battery.

In reverse mode, the OBC uses the EV’s stored DC power and employs a DC-AC inverter to convert it to AC. This AC power can be supplied back to the grid or used in home or office applications, such as providing energy to the grid during peak hours or powering a home during an emergency.

Despite the advantages of SiC devices in OBCs, challenges remain, such as manufacturing complexity, cost, safety, and reliability. Advanced manufacturing techniques, optimized production processes, and enhanced safety and reliability testing can help address these challenges.

As the EV market continues to grow, the performance and efficiency of OBCs will become increasingly critical. SiC devices will see broader application in OBCs, especially in high-power and high-efficiency scenarios. We can look forward to more research and technological advancements in this field, driving the adoption of SiC devices in OBCs to new heights.

In conclusion, the application of SiC devices in bidirectional OBCs offers significant advantages, including high-voltage handling, fast charging, energy efficiency, and thermal stability. However, challenges related to manufacturing, cost, safety, and reliability must be overcome through continuous research and innovation. The evolution of SiC in OBCs will provide the EV industry with more efficient and reliable charging solutions, making a greater contribution to environmental sustainability.

The Products You May Be Interested In

|

CC3500AC52-EC | AC/DC CONVERTER 52V 3500W | 274 More on Order |

|

AXA010A0P93-SR | DC DC CONVERTER 1.2V 12W | 358 More on Order |

|

ATM020A0X3-SR | DC DC CONVERTER 0.75-2V 40W | 125 More on Order |

|

APXK004A0X-SRDZ | DC DC CONVERTER 0.6-8V 32W | 109 More on Order |

|

LW010A6 | DC DC CONVERTER 5V 10W | 141 More on Order |

|

KNW020A0F1-88SRZ | DC DC CONVERTER 3.3V 66W | 303 More on Order |

|

QRW010A0B641Z | DC DC CONVERTER 12V 120W | 136 More on Order |

|

QBK033A0B41-HZ | DC DC CONVERTER 12V 396W | 296 More on Order |

|

EQW012A0A1Z | DC DC CONVERTER 5V 60W | 500 More on Order |

|

EQW006A0B1Z | DC DC CONVERTER 12V 72W | 200 More on Order |

|

EQW020A0F1-SZ | DC DC CONVERTER 3.3V 66W | 496 More on Order |

|

ATH010A0X43-SRZ | DC DC CONVERTER 0.8-3.6V 36W | 146 More on Order |

|

LW030A87 | DC DC CONVERTER 5V 30W | 415 More on Order |

|

LW005A | DC DC CONVERTER 5V 5W | 374 More on Order |

|

JW050A1 | DC DC CONVERTER 5V 50W | 261 More on Order |

|

JC100C1 | DC DC CONVERTER 15V 100W | 232 More on Order |

|

JC050A1 | DC DC CONVERTER 5V 50W | 305 More on Order |

|

HW005A0F-S | DC DC CONVERTER 3.3V 17W | 185 More on Order |

|

QBVE060A0S10R441-PHZ | DC DC CONVERTER 10.4V 625W | 499 More on Order |

|

KNW020A0F641-88Z | DC DC CONVERTER 3.3V 66W | 367 More on Order |

|

MDT040A0X3-SRPHDZ | DC DC CONVERTER 0.45-2V 80W | 459 More on Order |

|

ESTW010A0A41Z | DC DC CONVERTER 5V 50W | 439 More on Order |

|

KHHD006A0A41-SRZ | DC DC CONVERTER 5V 30W | 107 More on Order |

|

PVX003A0X3-SRZ | DC DC CONVERTER 0.6-5.5V 16.5W | 10104 More on Order |

Semiconductors

Semiconductors

Passive Components

Passive Components

Sensors

Sensors

Power

Power

Optoelectronics

Optoelectronics