Molex, the world's leading provider of electronic solutions, has introduced Percept, a new current sensor. The product is designed to meet the growing demand for high-precision busbar current sensing technology in the industrial and automotive sectors. By combining Infineon's wireless coil high-precision current sensing technology with Molex's unique electronic device packaging technology, the Percept sensor is optimized in terms of volume and weight, while significantly reducing the complexity of installation and system integration.

Lily Yeung, Director of the Sensor Business at Molex Automotive Innovation Solutions, said: "The new Percept current sensor, thanks to Infineon's wireless coil sensing technology and our unique electronic device packaging technology, sets a new industry benchmark for the accuracy, reliability and ease of integration of current detection. Together, we save our customers space while improving product performance and simplifying key design and manufacturing processes to reduce costs."

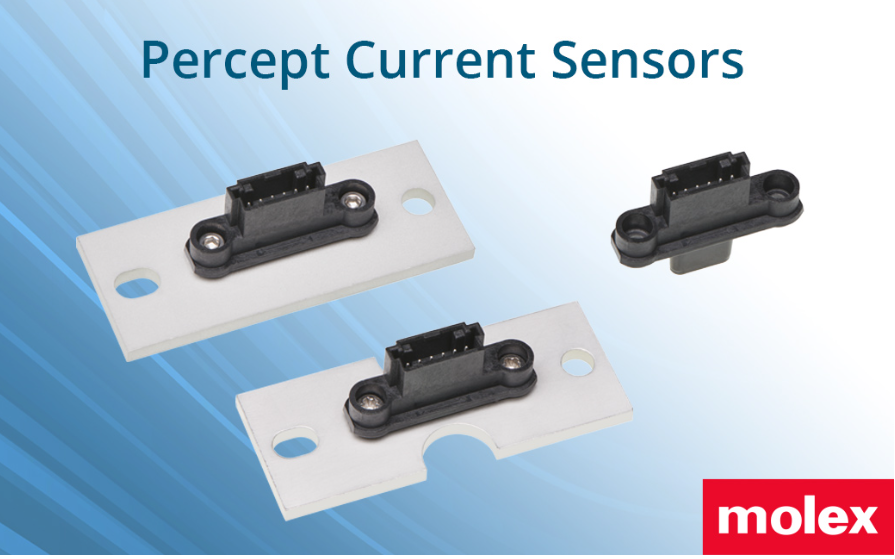

The Percept current sensor uses a compact wireless coil design and unique electronic device packaging technology, which is 86% lighter than similar products and only half the size. This allows us to achieve higher density integration inside the device, helping to reduce the weight of the overall system while increasing the flexibility of the design.

Molex's Percept current sensors are also capable of sensing in environments with limited space and sensitivity to electromagnetic interference (EMI). These sensors provide measurement accuracy of less than 2% over a wide temperature range and throughout the product life cycle, while exhibiting low sensitivity to interference signals and device offset errors. In addition, Infineon's differential Hall effect sensors are designed to withstand interference from stray magnetic fields, which are common in demanding industrial motor drives and automotive applications.

Matthias Grewe, Vice President and Head of the Magnetic Sensing product line at Infineon Technologies, said: "Infineon's XENSIV™ TLE4973 and TLE4972 are part of our family of high-precision wireless coil magnetic current sensors, which measure from 0 to 2000 amps and are therefore flexible to accommodate a very large power range. When combined with Infineon's sensors, Molex's innovative packaging technology creates a small, efficient and powerful solution for the automotive and industrial markets."

Molex's unique electronic device packaging technology integrates high-current conductors, connectors, printed circuit boards (PCBS), bus bars, heat sinks and other mechanical components into a single device. This technology is particularly suitable for devices that need to withstand extreme temperatures, high currents and harsh environments. The packaging technology of Percept current sensors not only ensures the flexibility of system integration, but also improves the measurement accuracy through precise chip placement and factory calibration. The pre-calibrated system simplifies the installation process and significantly reduces assembly time.

This novel packaging technology uses 99% less water than typical printed circuit board manufacturing techniques, and does not require any chemicals or produce copper etching waste mud, making the manufacturing process more environmentally friendly. Versatile and configurable design options, including sensors built into the bus, provide customers with a complete plug and play deployment package, so it does not require excessive development time, resources or costs.

The Products You May Be Interested In

|

62045-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 135 More on Order |

|

62044-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 336 More on Order |

|

62043-P2S02 | XFRMR TOROIDAL 10VA CHAS MOUNT | 304 More on Order |

|

62035-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 369 More on Order |

|

62025-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 218 More on Order |

|

62005-P2S02 | XFRMR TOROIDAL 1.6VA CHAS MOUNT | 426 More on Order |

|

62075-P2S02 | XFRMR TOROIDAL 35VA CHAS MOUNT | 406 More on Order |

|

62073-P2S02 | XFRMR TOROIDAL 35VA CHAS MOUNT | 294 More on Order |

|

70072K | XFRMR TOROIDAL 35VA THRU HOLE | 313 More on Order |

|

70054K | XFRMR TOROIDAL 15VA THRU HOLE | 262 More on Order |

|

70043K | XFRMR TOROIDAL 10VA THRU HOLE | 309 More on Order |

|

70024K | XFRMR TOROIDAL 5VA THRU HOLE | 486 More on Order |

|

70013K | XFRMR TOROIDAL 3.2VA THRU HOLE | 244 More on Order |

|

70011K | XFRMR TOROIDAL 3.2VA THRU HOLE | 420 More on Order |

|

70003K | XFRMR TOROIDAL 1.6VA THRU HOLE | 140 More on Order |

|

70002K | XFRMR TOROIDAL 1.6VA THRU HOLE | 280 More on Order |

|

70025K | XFRMR TOROIDAL 5VA THRU HOLE | 226 More on Order |

|

62082-P2S02 | XFRMR TOROIDAL 50VA CHAS MOUNT | 277 More on Order |

|

62033-P2S02 | XFRMR TOROIDAL 7VA CHAS MOUNT | 360 More on Order |

|

62024-P2S02 | XFRMR TOROIDAL 5VA CHAS MOUNT | 268 More on Order |

|

62084-P2S02 | XFRMR TOROIDAL 50VA CHAS MOUNT | 607 More on Order |

|

70064K | XFRMR TOROIDAL 25VA THRU HOLE | 2293 More on Order |

|

70005K | XFRMR TOROIDAL 1.6VA THRU HOLE | 401 More on Order |

|

AC1025 | TRANSFORMER CURRENT 25.0 AMP | 235 More on Order |

Semiconductors

Semiconductors

Passive Components

Passive Components

Sensors

Sensors

Power

Power

Optoelectronics

Optoelectronics