In the global trend towards sustainable development, new energy vehicles have attracted wide attention due to their low carbon emissions and high energy efficiency. With this comes an increasing demand for high-performance power electronics. Silicon carbide (SiC) power devices, with their excellent electrical and thermal properties, are becoming a key component of the core power system of new energy vehicles. By improving energy conversion efficiency, SiC power devices play an important role in improving the endurance of electric vehicles.

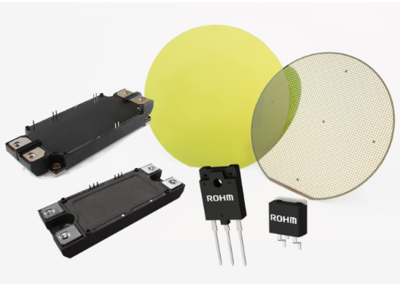

Unique advantages of SiC materials

As a wide band gap semiconductor material, SiC has multiple advantages. First, SiC has a bandgap about three times that of silicon and is able to operate at higher voltages and higher temperatures. This feature enables SiC power devices to withstand larger power loads, thereby improving the overall efficiency of the power conversion system. Second, the thermal conductivity of SiC is much higher than that of silicon, allowing it to dissipate heat better when operating at high temperatures, reducing the need for complex cooling systems. This not only reduces the weight of the vehicle, but also simplifies the design and improves the space utilization of the vehicle.

The key to improving battery life: Efficient energy conversion

In the power transmission system of new energy vehicles, the energy conversion efficiency between the battery and the motor directly affects the endurance. SiC power devices are particularly prominent at this point. When the traditional silicon-based devices perform high-frequency switching, the energy is wasted due to the high switching loss. In contrast, SiC devices have significantly lower switching losses at high frequency operation, meaning that more electrical energy can be used to drive the motor.

SiC MOSFETs, for example, reduce switching losses by about 30% compared to traditional silicon MOSFETs. This advantage not only improves the driving efficiency of the motor, but also indirectly extends the range of the battery. In addition, the excellent performance of SiC power devices at high frequencies can make the ADC-03RMMS-SC7001 inverter smaller and lighter, thereby improving the performance of the entire vehicle.

System integration and power density

In the power transmission of electric vehicles, the design of inverters, DC-DC converters and other power electronic modules is crucial. The high energy density and miniaturization of SiC power devices allow these components to be more compact when designed, helping manufacturers design more competitive and high-performance electric vehicles. Miniaturized inverters and DC-DC converters not only save space, but also reduce the weight of the vehicle, which directly affects the endurance of the car.

For example, power modules based on SiC technology have the potential to achieve more than 50% volume reduction and more than 30% energy efficiency improvement compared to traditional silicon technology. This reduces the weight of the vehicle while improving its energy conversion efficiency, providing positive support for the endurance of electric vehicles.

Improved charging efficiency

In addition to enhancing the endurance of new energy vehicles, SiC power devices also perform well in terms of charging speed. Traditional chargers mostly use silicon-based power devices, and the charging efficiency is generally low. The fast charger using SiC technology can complete the charge in a shorter time, while maintaining high efficiency. This feature has attracted the attention of many automobile manufacturers and charging pile service providers, and has become an important part of improving user experience.

Among the many solutions to improve charging efficiency, the application of SiC technology enables charging equipment to charge electric vehicles more quickly and safely, which greatly facilitates user travel and enhances the market competitiveness of new energy vehicles.

Durability and safety

The power system of new energy vehicles must have excellent durability and safety. The reliability of SiC power devices in resisting high temperatures, high voltages and harsh operating environments makes them ideal for electric vehicles. In addition, the high thermal conductivity of SiC material reduces the risk of performance degradation due to heat and improves the stability of the system.

In new energy vehicles, safety is crucial, especially when it comes to battery management systems and motor control. The high voltage resistance and low failure rate of SiC power devices make them a reliable power solution for the safety of the vehicle. At the same time, the use of SiC technology increases the redundancy of the system, thereby reducing the potential risk of failure. This feature is especially important in long-distance driving and high frequency usage scenarios, providing users with a more secure driving experience.

Future outlook

With the rapid growth of the electric vehicle market, SiC power devices will continue to play an important role. The research and development industry has begun to focus on how to better combine SiC technology with other new energy technologies, such as hydrogen fuel cells, to further improve the overall efficiency of new energy vehicles. In the future, with the improvement of SiC production technology and the reduction of costs, it is expected that its application in electric vehicles will be more extensive.

At the same time, the improvement of relevant regulations and standards will also provide a reliable environment for the application of SiC power devices and promote the healthy development of the entire industry. As an important part of future mobility, the power of SiC power devices will be an indispensable part to achieve further endurance goals and contribute to sustainable development.

The Products You May Be Interested In

|

3102 | JOYSTICK 10K OHM 2 AXIS PNL MT | 413 More on Order |

|

3350 | RUGGED METAL PUSHBUTTON | 183 More on Order |

|

1191 | SWITCH PUSHBUTTON SPST-NO YELLOW | 495 More on Order |

|

1190 | SWITCH PUSHBUTTON SPST-NO RED | 445 More on Order |

|

1192 | SWITCH PUSHBUTTON SPST-NO WHT | 582 More on Order |

|

3432 | SWITCH PUSH SPST-NO BLU 10MA 5V | 577 More on Order |

|

3490 | SWITCH PUSH SPST-NO BLU 10MA 5V | 415 More on Order |

|

1767 | SLOW VIBRATION SENSOR SWITCH (HA | 2751 More on Order |

|

2553 | DIGITAL RGB LED WEATHERPROOF STR | 339 More on Order |

|

2540 | NEOPIXEL DIGITAL RGB LED STRIP - | 216 More on Order |

|

1050 | ADDRESS LED MATRIX I2C YELLOW | 465 More on Order |

|

1558 | ADDRESS LED MODULE SER RGB 1=25 | 319 More on Order |

|

2237 | ADDRESS LED STRIP SERIAL RGB 1M | 418 More on Order |

|

1376 | ADDRESS LED STRIP SERIAL RGB 5M | 402 More on Order |

|

3094 | ADDRESS LED DISCR SER RGB 100PK | 499 More on Order |

|

2761 | ADDRESS LED DISCR SER RGBW 1=10 | 607 More on Order |

|

4245 | FLEXIBLE RGB NEON-LIKE LED STRIP | 356 More on Order |

|

188 | GRAPHIC KS0108 LCD 128X64 + EXTR | 244 More on Order |

|

1816 | 10 SEGMENT LIGHT BAR WHITE | 307 More on Order |

|

399 | RGB BACKLIGHT NEGATIVE LCD | 410 More on Order |

|

784 | USB + SERIAL BACKPACK KIT | 247 More on Order |

|

2973 | LED CHARLIEPLEXED MATRIX - 9X16 | 368 More on Order |

|

1484 | 32X32 RGB LED MATRIX PANEL 6MM P | 297 More on Order |

|

1681 | VS1053B MP3/WAV/OGG/MIDI PLAYER | 465 More on Order |

Semiconductors

Semiconductors

Passive Components

Passive Components

Sensors

Sensors

Power

Power

Optoelectronics

Optoelectronics